Smart Grain Elevator Systems Using IoT: Transforming Modern Agriculture

Written by:

Kostiantyn Oliynyk

Head of IoT at Webbylab

With a robust academic background in Telecommunication Systems Engineering, I apply my knowledge to lead innovations in the IoT domain. Starting as the first team member in the newly formed IoT department at WebbyLab, I've spearheaded its growth, fostering the expansion into embedded and hardware development alongside our core software projects. My dedication lies in pushing the boundaries of IoT technology, fostering a culture of innovation and excellence that profoundly impacts our clients' operational success.

Farm elevator systems using IoT offer numerous benefits, including improved operational efficiency, reduced costs, enhanced grain quality, increased safety, real-time monitoring, and predictive maintenance.

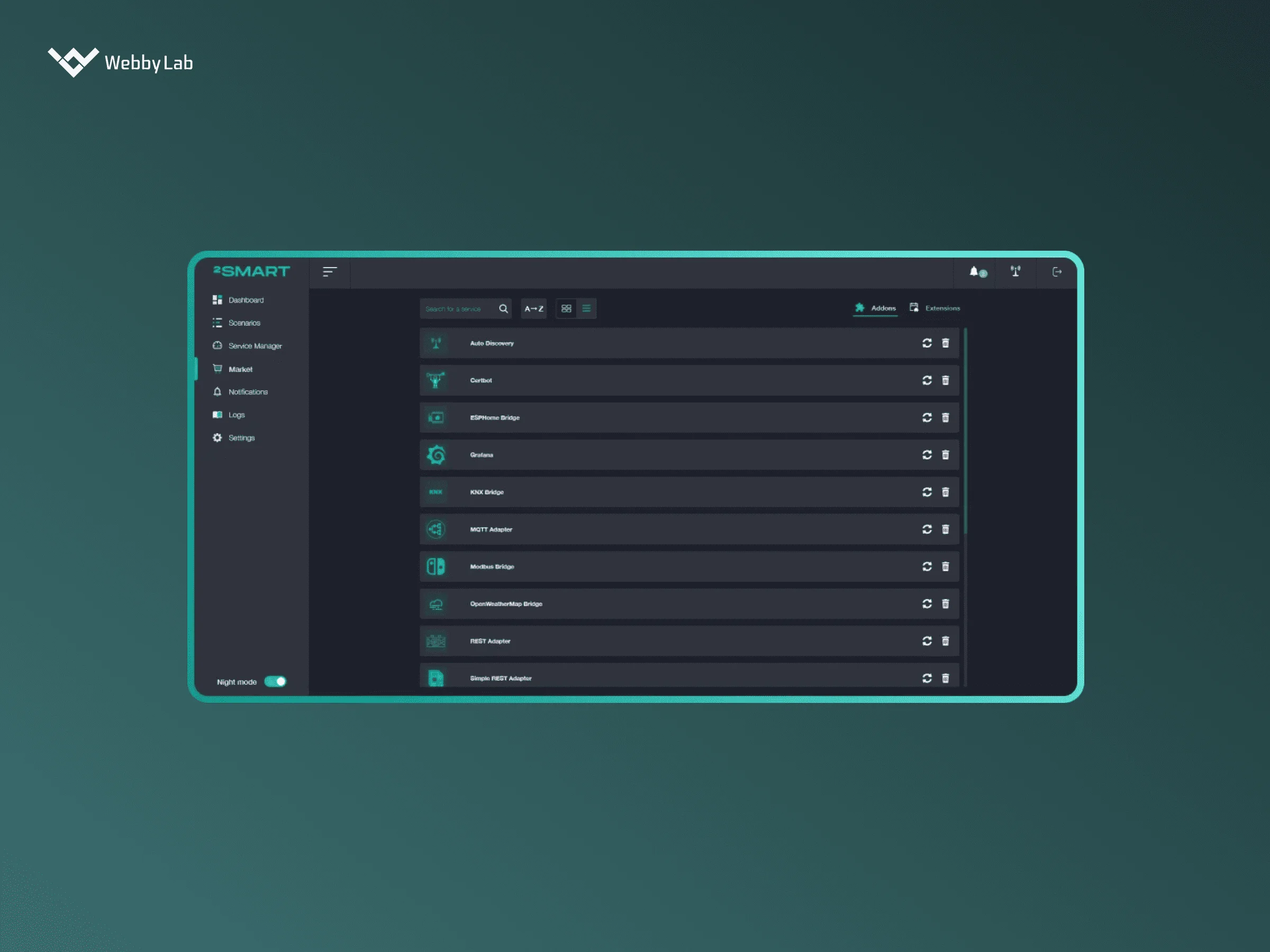

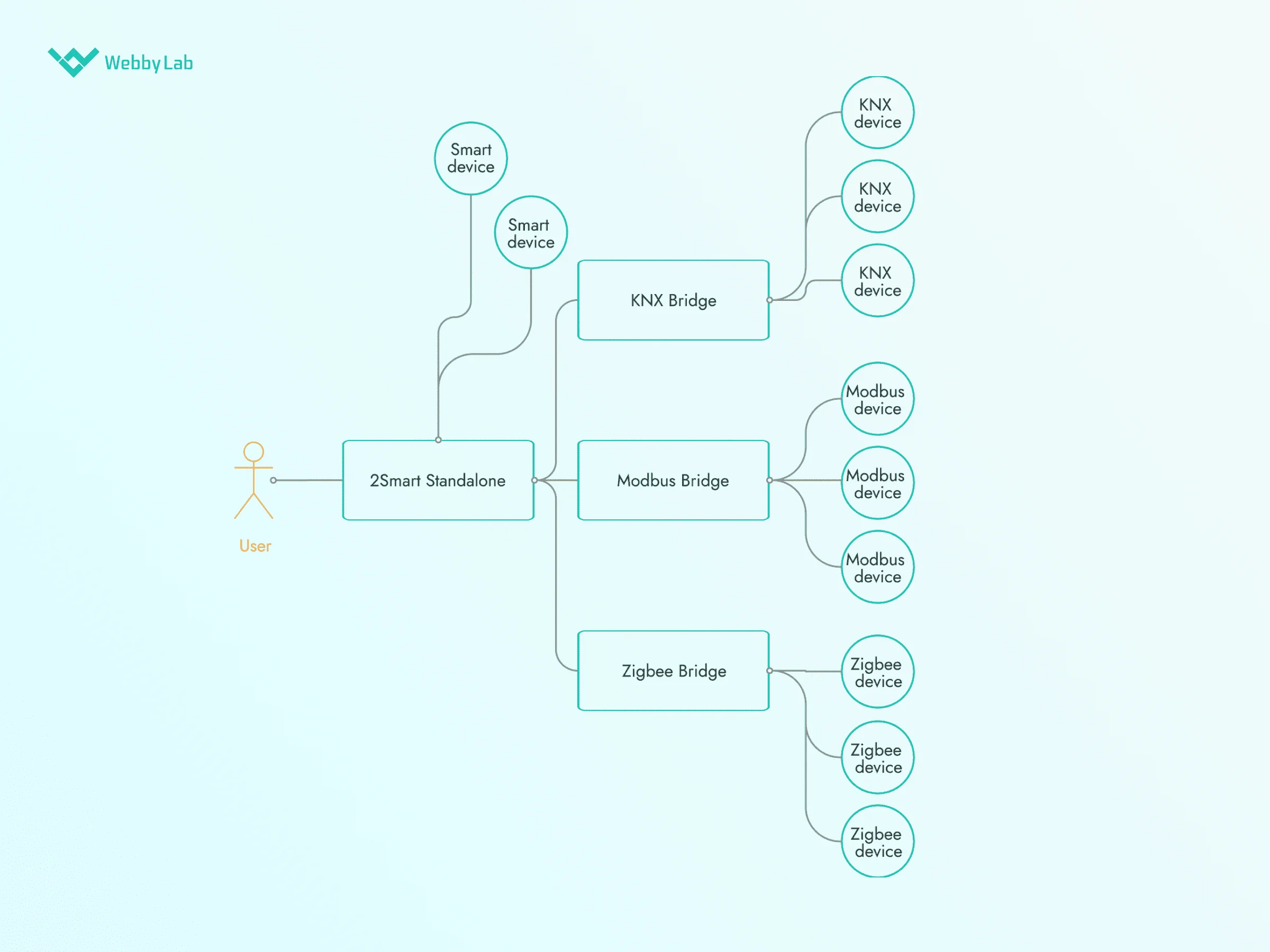

WebbyLab can assist grain elevator owners in implementing IoT solutions tailored to their specific needs. With our 2Smart Standalone platform, businesses can automate grain storage and monitoring, streamlining operations and maximizing efficiency.

Some IoT devices include environmental, pressure, level, and moisture sensors, as well as security, surveillance, and control systems.

Businesses may encounter such challenges as legacy IT infrastructure, data security concerns, connectivity issues, and the necessity to manage large volumes of data generated by IoT devices.

This is one of the most popular IoT grain storage questions. Elevator IoT technology improves grain storage with real-time monitoring of temperature, humidity, and grain levels — ultimately reducing spoilage and preventing losses. Plus, automated control systems adjust ventilation and aeration, ensuring optimal storage conditions, while predictive analytics optimizes inventory management and reduces energy consumption.

The smart elevator costs USA depend on scale, automation level, and integration requirements. Small-scale IoT solutions for agriculture in the USA start at $15,000–$25,000, while fully automated grain handling and analytics systems can cost $50,000 or more. That said, the long-term savings from reduced grain loss, low energy consumption, and labor optimization promise a high ROI.

Of course! Automated grain storage systems USA are typically scalable and can be adapted for small farms. Affordable sensor systems let farmers monitor storage conditions without pricey infrastructure. Cloud platforms allow remote management, cutting down on manual checks and making IoT a budget-friendly option, even for smaller operations.