Top 5 Use Cases of Predictive Maintenance using IoT

Written by:

Kostiantyn Oliynyk

Head of IoT at Webbylab

With a robust academic background in Telecommunication Systems Engineering, I apply my knowledge to lead innovations in the IoT domain. Starting as the first team member in the newly formed IoT department at WebbyLab, I've spearheaded its growth, fostering the expansion into embedded and hardware development alongside our core software projects. My dedication lies in pushing the boundaries of IoT technology, fostering a culture of innovation and excellence that profoundly impacts our clients' operational success.

FAQ

How does predictive maintenance enhance safety in the transportation industry?

It collects and analyzes real-time data from vehicles, sending instant alerts in case of failures or potential breakdowns. This way, transportation companies can keep their vehicles in optimal condition, ultimately preventing accidents and improving road safety.

Are there any emerging technologies influencing the future of IoT-based predictive maintenance?

Yes, and the most prominent of them are edge computing and 5G connectivity. One innovation enables faster data processing, while another enhances data transmission speed.

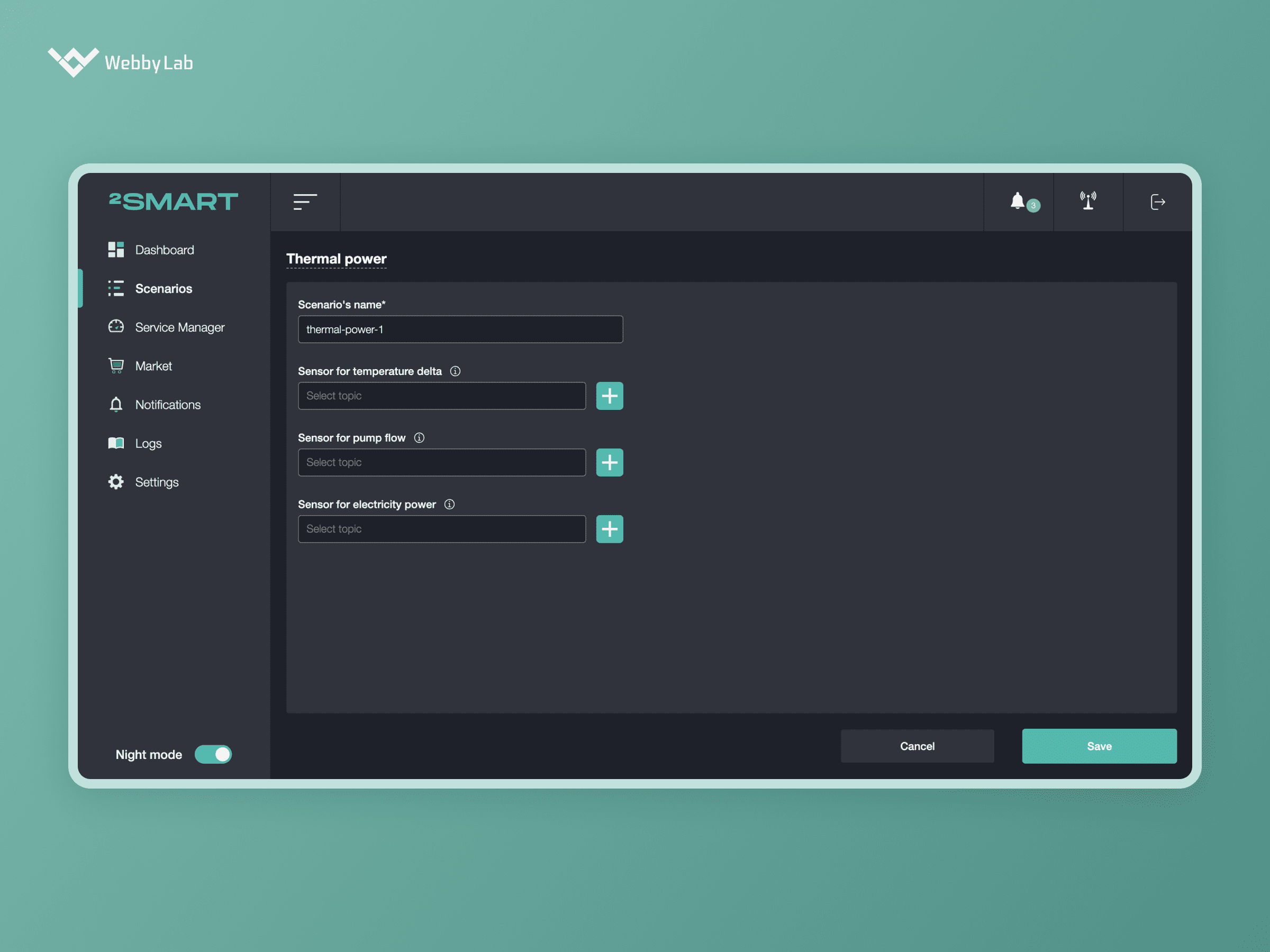

Can IoT-based predictive maintenance be customized for specific equipment types?

Yes, it’s highly adaptable. Businesses can customize everything for their equipment maintenance needs, from sensor selection to predictive analysis model development.

How does predictive maintenance with IoT impact cost efficiency?

It minimizes downtime and prevents businesses from having to make unscheduled repairs. Therefore, companies can schedule maintenance tasks in advance, allocating their resources wisely.

How accurate are IoT predictive maintenance predictions?

The accuracy of IoT predictive maintenance predictions can vary widely depending on the quality of data, the sophistication of the predictive algorithms, and the specific use case. In general, when implemented properly, IoT predictive maintenance can be highly accurate, often achieving prediction accuracies above 90%.