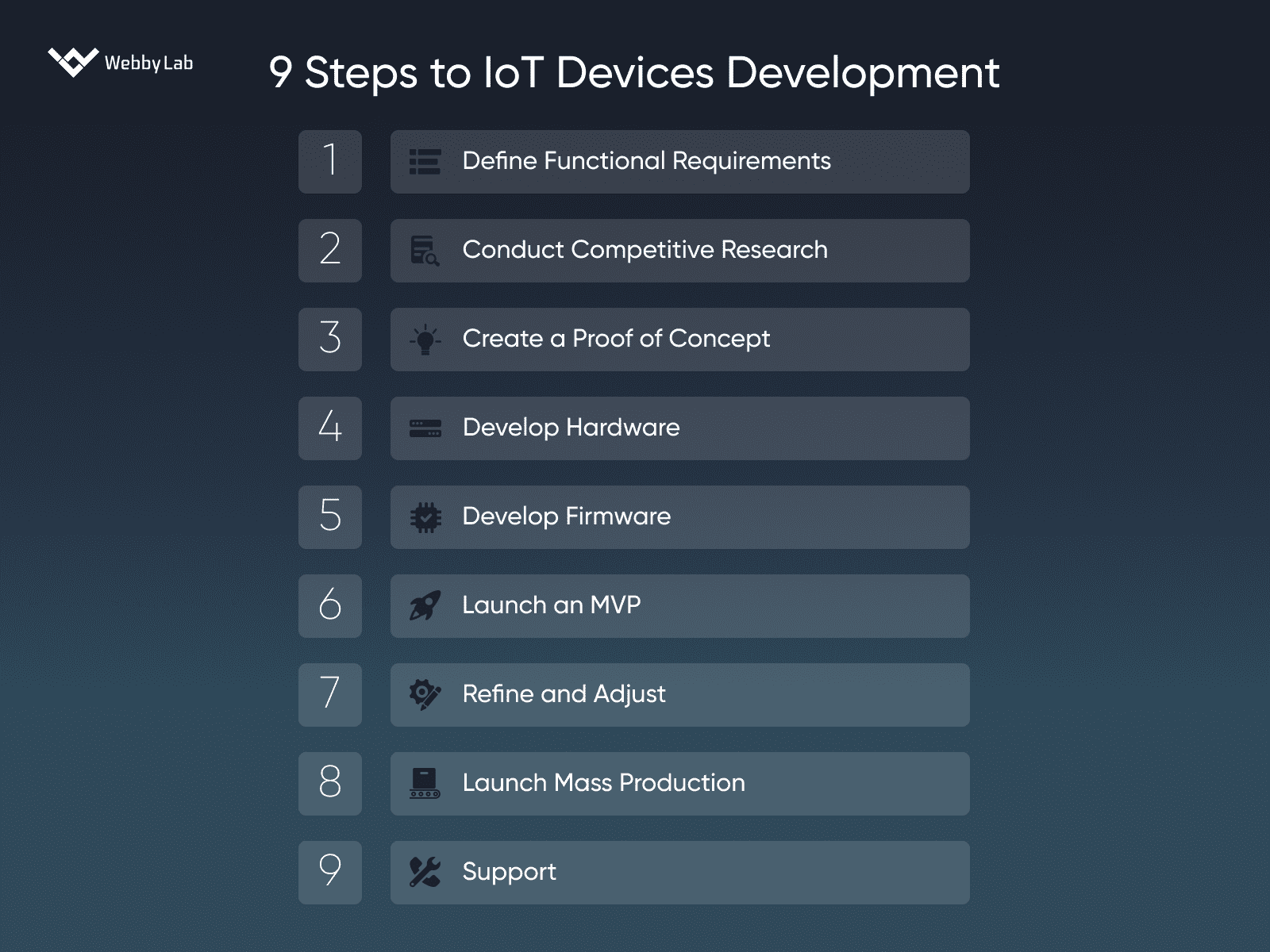

IoT Product Development [Explained]: 9 Steps to Production

Written by:

Kostiantyn Oliynyk

Head of IoT at Webbylab

With a robust academic background in Telecommunication Systems Engineering, I apply my knowledge to lead innovations in the IoT domain. Starting as the first team member in the newly formed IoT department at WebbyLab, I've spearheaded its growth, fostering the expansion into embedded and hardware development alongside our core software projects. My dedication lies in pushing the boundaries of IoT technology, fostering a culture of innovation and excellence that profoundly impacts our clients' operational success.

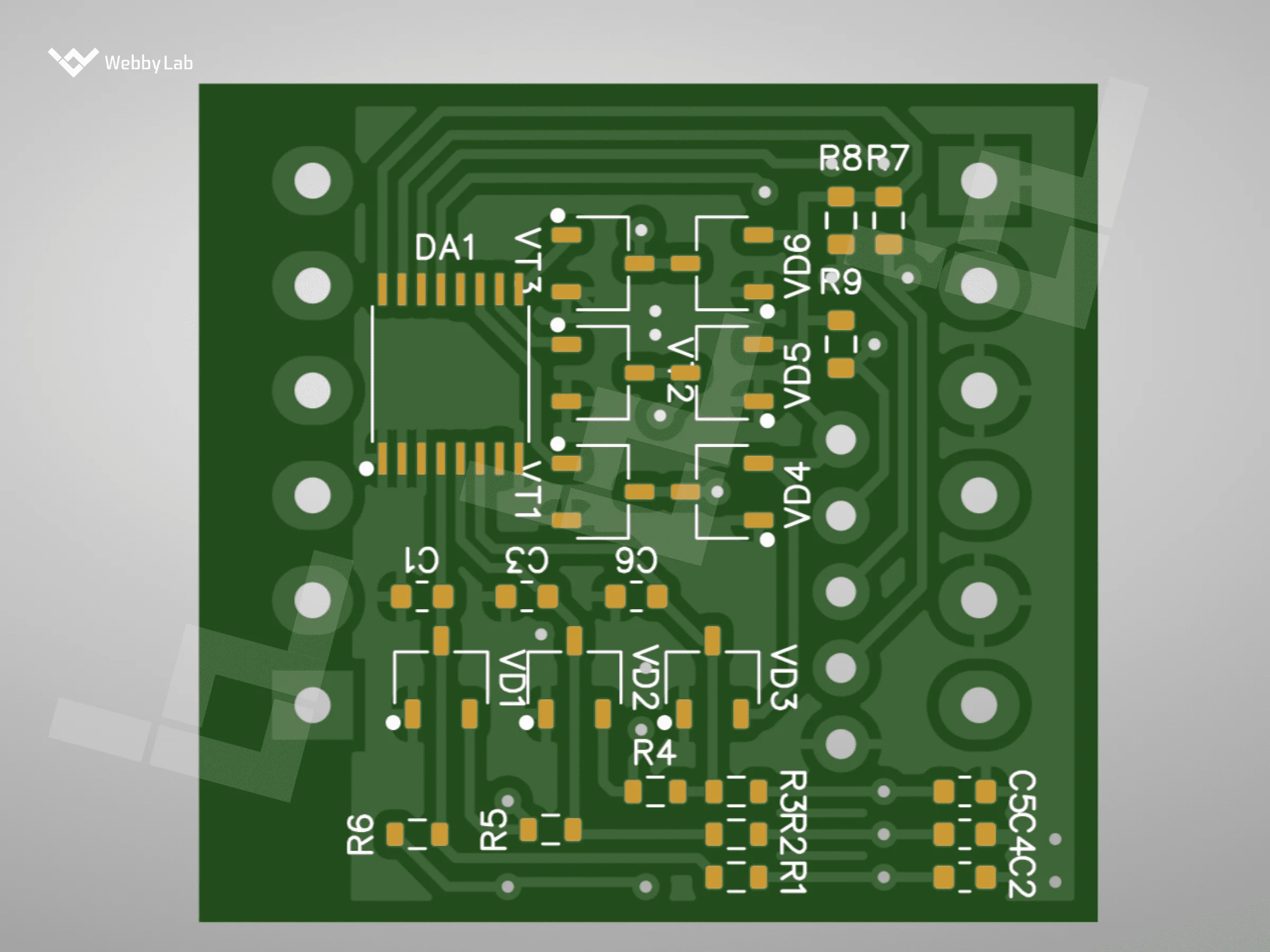

The IoT hardware development requirements concern security, connectivity, power, physical device design, data processing and storage, and cost.

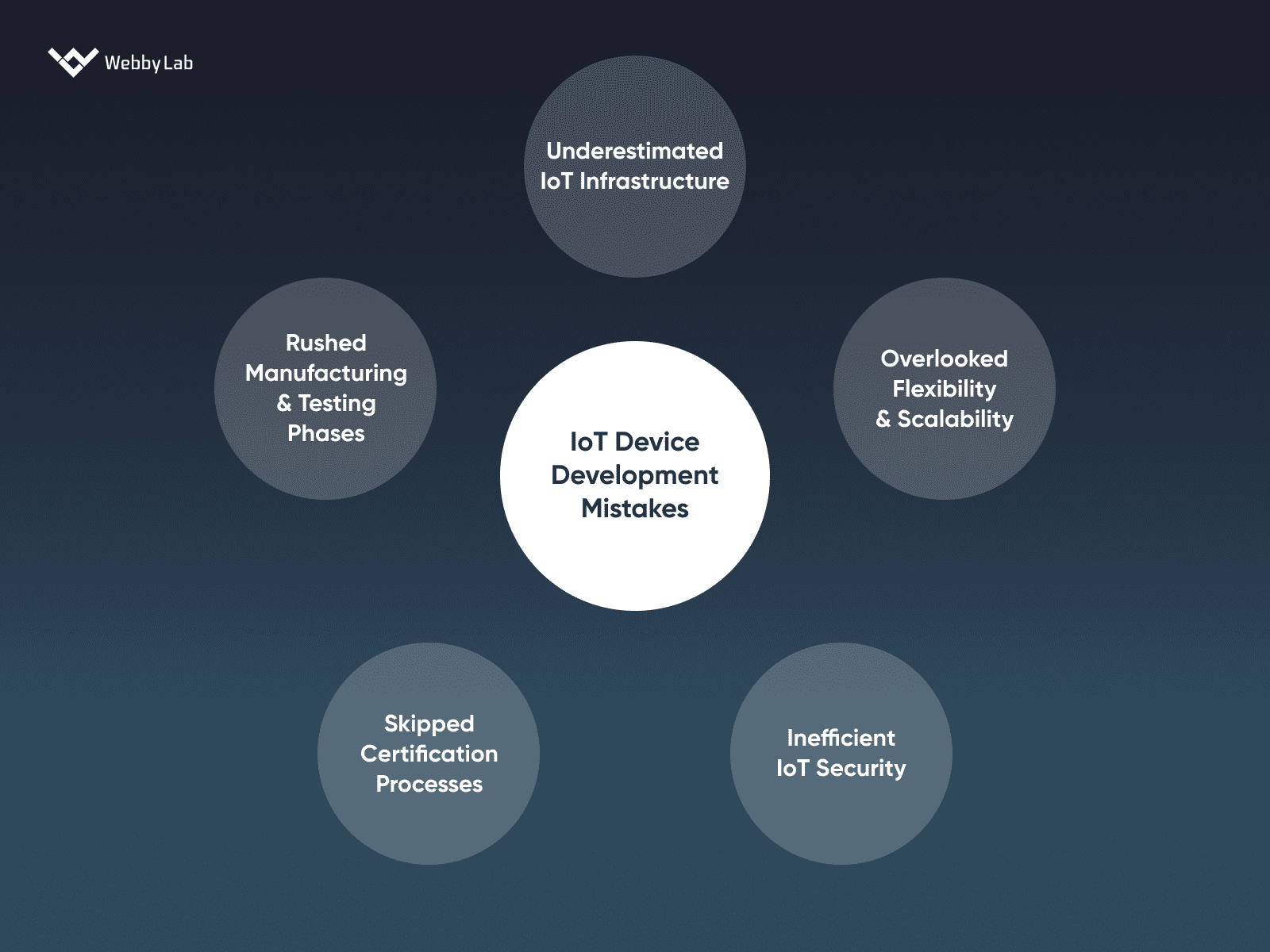

The IoT product development is facing two basic categories of challenges:

- Technological: issues with connectivity, security, standardization, smart data analysis, and compatibility.

- Business: an emerging demand in large-scale manufacturing, simplified usability, device compatibility, software maintenance, etc.

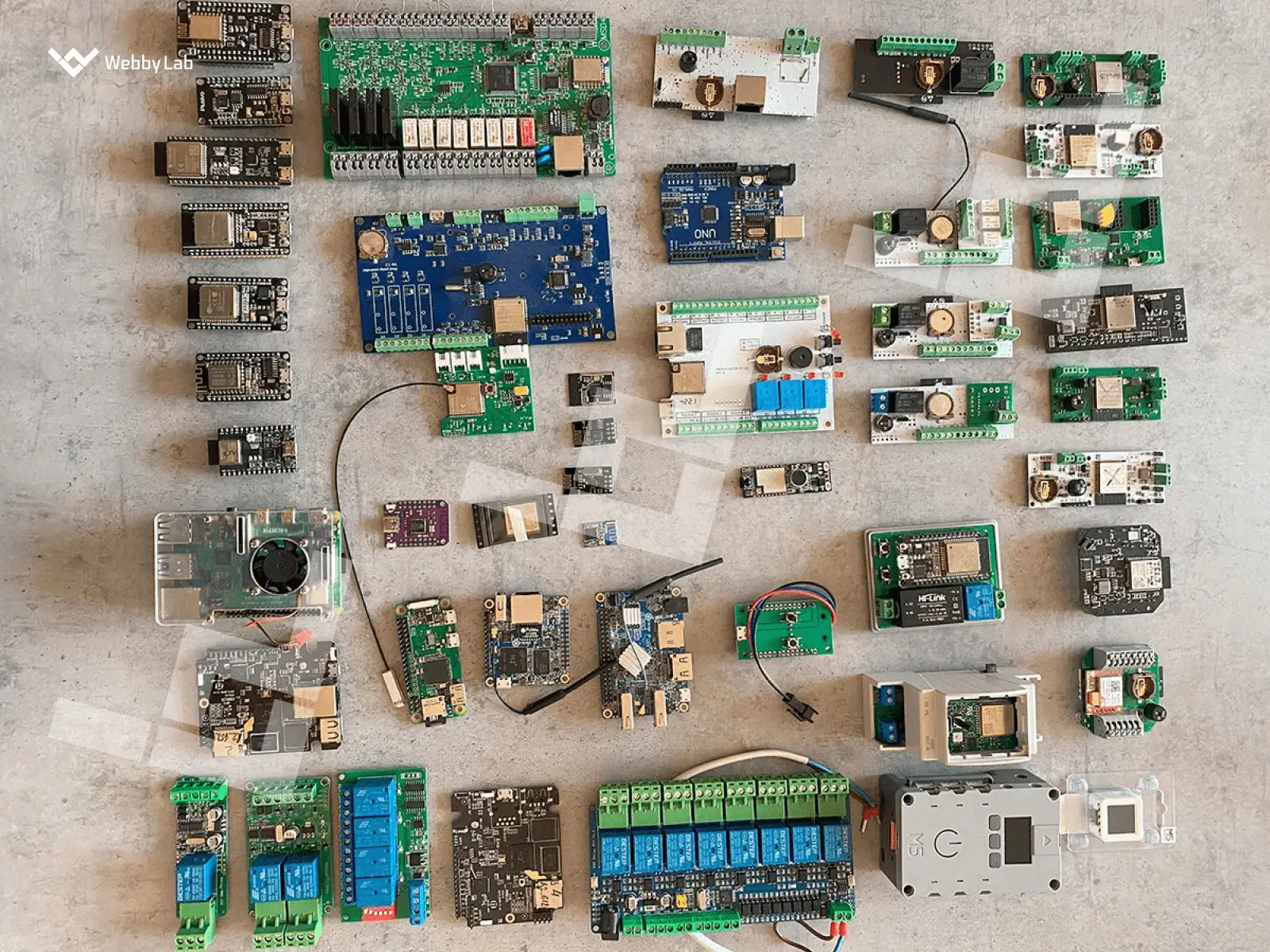

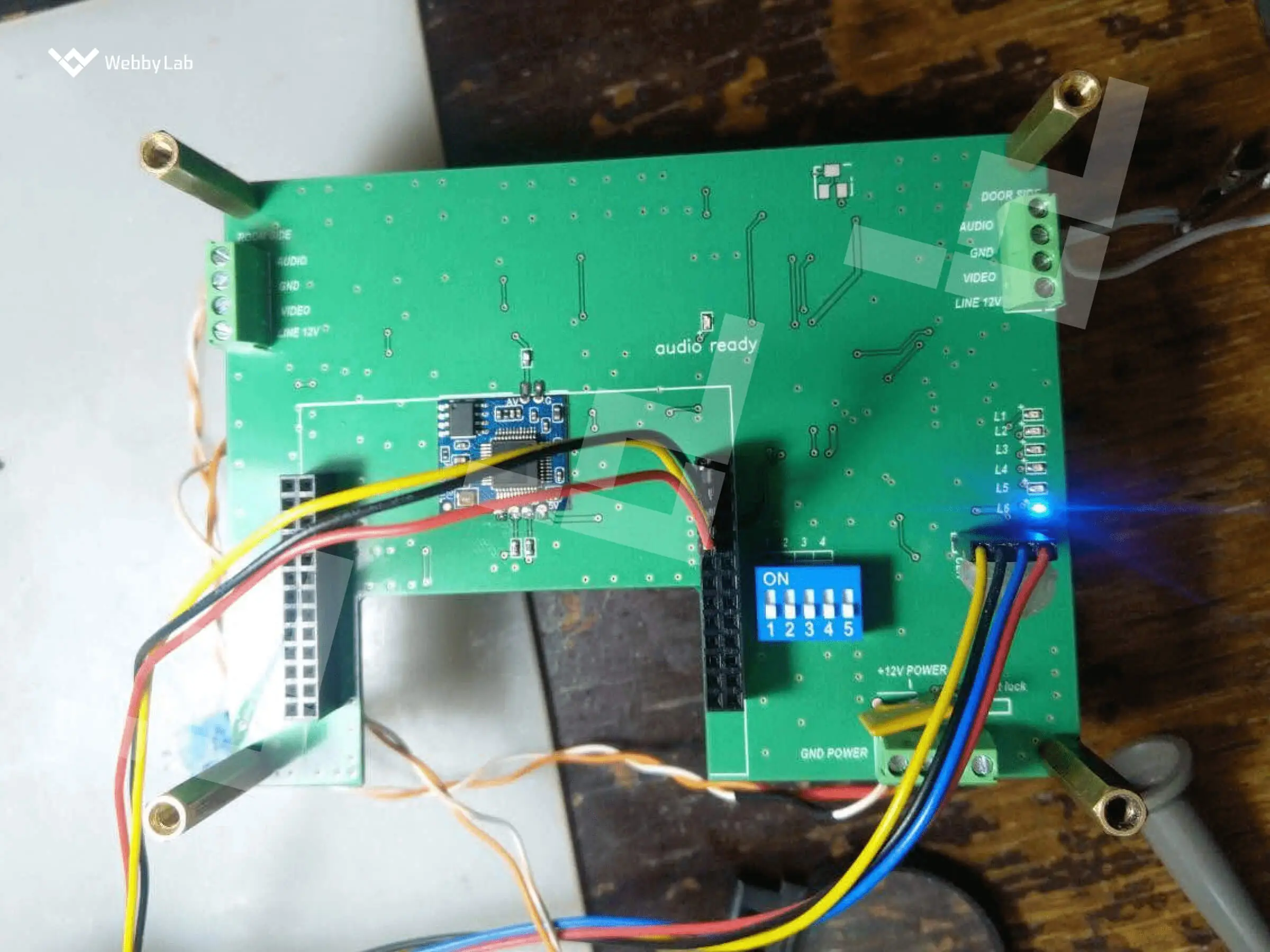

According to our experience in IoT product development, the customization of pre-made and test-proven solutions is always cheaper and more effective than development from scratch.

Once you’ve decided to hire IoT hardware experts for your project, selecting the best contractors will require three basic stages:

- Market research, covering various aspects of the potential vendors, from their services to the minimal project costs and expertise within a particular industry;

- Technical analysis, during which you check the tech stack and equipment the company offers, research their development methodologies;

- Meeting to discuss all technical and organizational aspects. After that, you can make a final decision.

![IoT Product Development [Explained]: 9 Steps to Production](https://webbylab.com/wp-content/webp-express/webp-images/uploads/2024/10/upload_671fa7a3c3f6f-791x267.png.webp)

![How to Hire IoT Developers [Guide from Experts in IoT]](https://webbylab.com/wp-content/webp-express/webp-images/uploads/2022/12/banner_hiring-iot-768x260.png.webp)