How IoT in Quality Control Is Supporting Hardware Production

Written by:

Kostiantyn Oliynyk

Head of IoT at Webbylab

With a robust academic background in Telecommunication Systems Engineering, I apply my knowledge to lead innovations in the IoT domain. Starting as the first team member in the newly formed IoT department at WebbyLab, I've spearheaded its growth, fostering the expansion into embedded and hardware development alongside our core software projects. My dedication lies in pushing the boundaries of IoT technology, fostering a culture of innovation and excellence that profoundly impacts our clients' operational success.

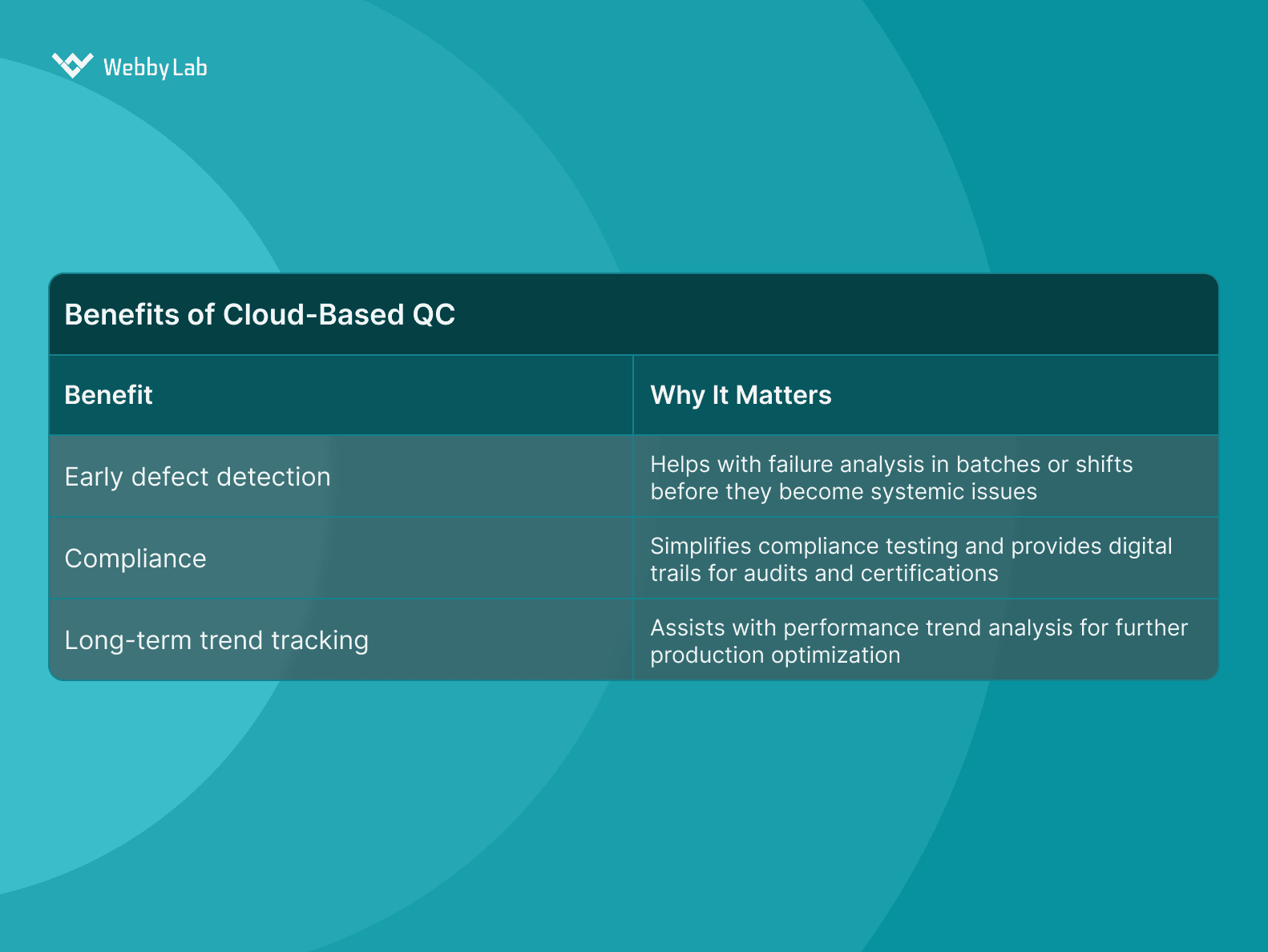

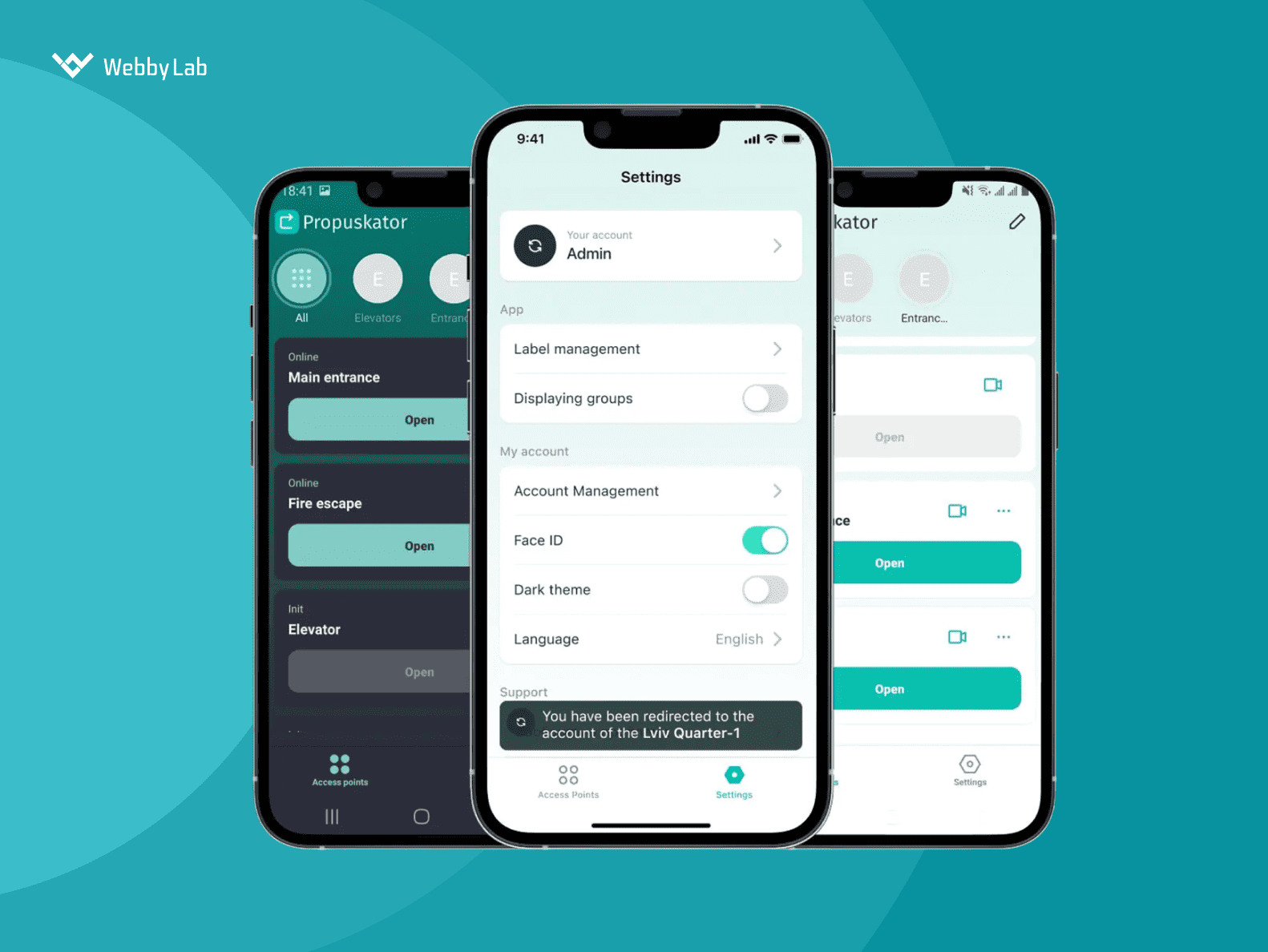

Most of such tools are made for large-scale operations with fixed setups, but WebbyLab brings flexibility into embedded systems, prototyping validation, and custom devices. We implement IoT technologies for quality control (including edge computing, remote diagnostics, and cloud-based analytics) to fit into your production flow. That means you get all the benefits of enhanced quality control through IoT.

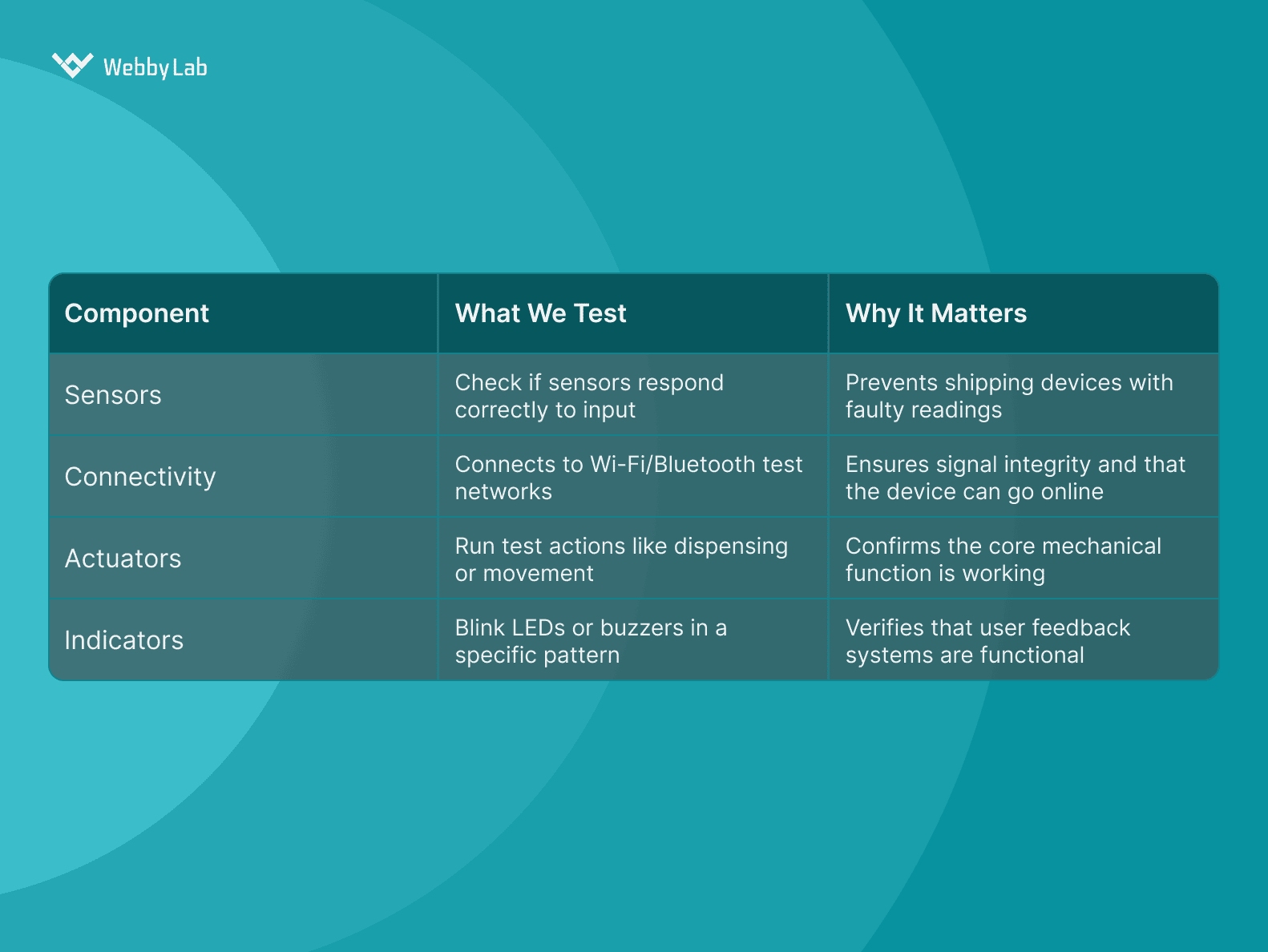

Improve QC by integrating IoT sensors in quality control workflows for predictive maintenance along with real-time and condition-based monitoring. Plus, pay close attention to firmware and cloud-based QC procedures. Tools like digital twins, factory floor analytics, and intelligent inspection systems (including AI-based inspections) also help refine manufacturing KPIs.

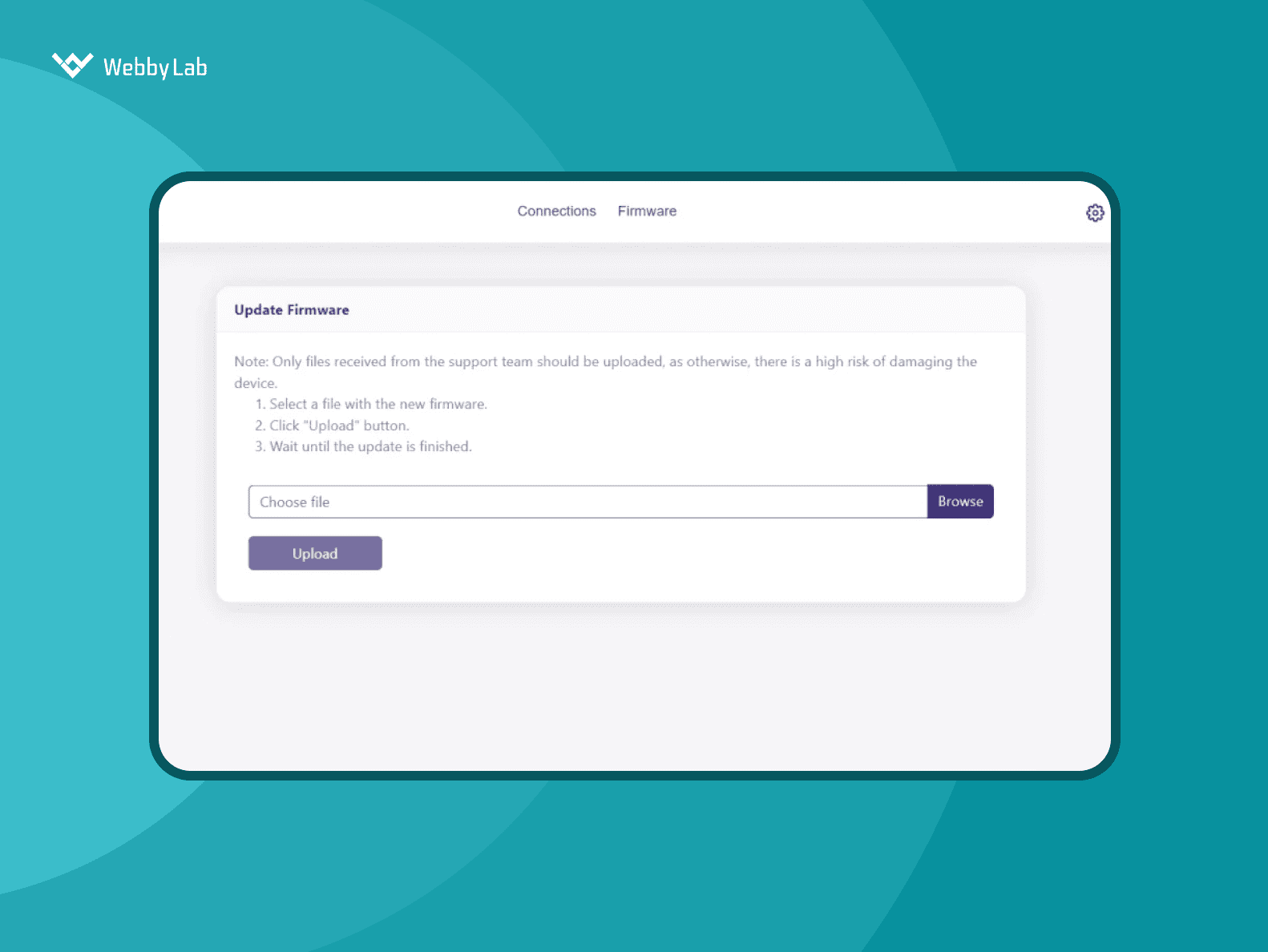

When manufacturing electronics, such as home IoT devices, include firmware-level testing, automated test rigs, and cloud-based data pipelines. Implement IoT for enhanced quality control through process automation.

Manufacturing tracking software combined with IoT improves quality control in manufacturing by collecting and analyzing data from industrial IoT sensors, test rigs, and inspection systems. It doesn’t just power smart manufacturing but also turns QC into a proactive process that boosts operational efficiency and contributes to downtime reduction.